Ravi Kumar Darji

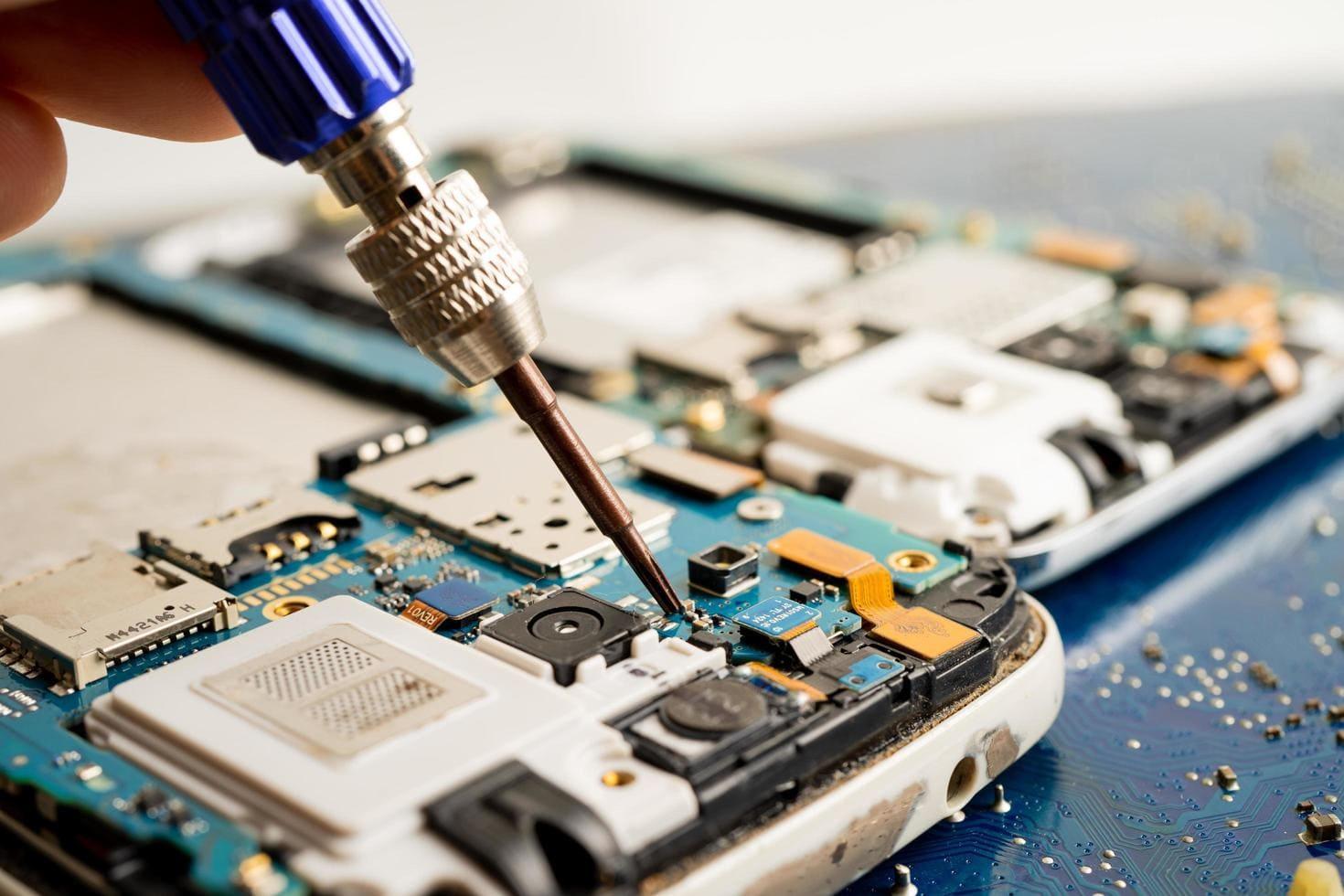

Repair or Replace? Making the Eco-Conscious Choice for Your Tech

TalentRiseCluster has successfully deployed an advanced IT Asset Lifecycle Management (ITAM) platform. This new system centralizes the tracking, monitoring, and strategic management of all technological assets. It integrates sophisticated analytics, providing data-driven insights crucial for optimizing equipment lifespan and making informed repair-versus-replacement decisions, thereby enhancing operational efficiency and reinforcing sustainable practices.

Previously, managing TalentRiseCluster's diverse IT assets involved fragmented tracking and manual data compilation. This resulted in a lack of real-time visibility, inconsistent maintenance, and challenges in accurately assessing total cost of ownership. Such limitations often led to suboptimal decisions, increasing operational expenditures and contributing to a larger environmental footprint.

The ITAM platform's development involved a dedicated cross-functional team, prioritizing scalable architecture and robust data integration. The process included requirements gathering, iterative development, and comprehensive internal testing. Following successful testing, a controlled pilot launch provided critical feedback for final refinements. This culminated in a seamless, phased full deployment across all relevant operational units.

Internally, the new ITAM platform streamlines and automates asset management workflows. It provides a centralized, real-time repository for all equipment data, including warranty and repair history. This empowers IT and procurement teams to make data-backed decisions on maintenance and end-of-life strategies. Assessing repair viability over replacement directly influences equipment longevity, reducing electronic waste. Improved efficiency and reduced environmental impact support TalentRiseCluster's sustainability goals.

Deployment of the ITAM platform has yielded immediate and measurable results. We observe enhanced operational transparency and significant improvements in decision-making speed for asset disposition. Initial data indicates a projected reduction in equipment turnover rates by optimizing repair cycles and extending asset useful life. The platform also provides precise understanding of total cost of ownership, enabling strategic budgeting. This translates into improved resource efficiency, minimized environmental footprint, and greater cost-effectiveness.

0 Comments